Description:

Extreme Thermal Resilience: Capable of withstanding destructive temperatures up to 450°C with exceptional flame-retardant properties.

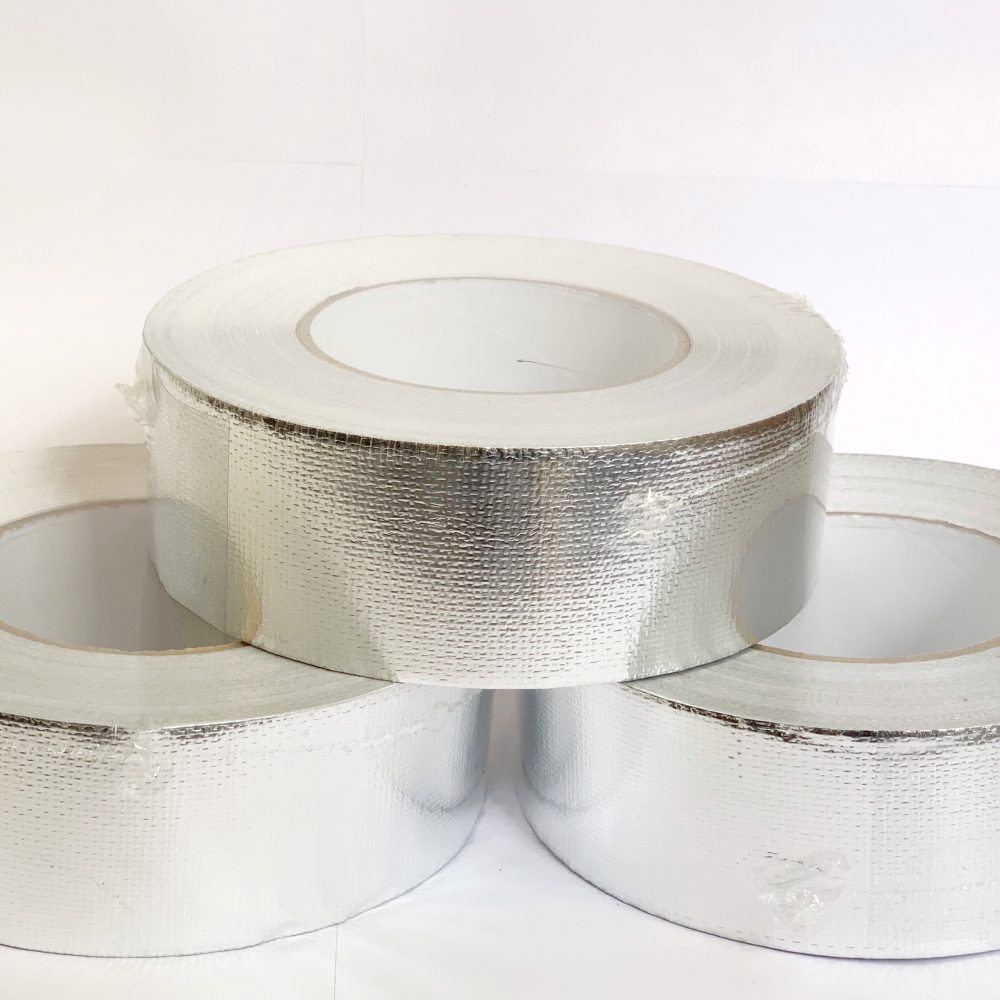

Fiberglass Reinforcement: The integrated fiberglass mesh provides high tensile strength, ensuring the tape remains tear-resistant under heavy tension.

High-Performance Adhesive: Formulated with a powerful acrylic adhesive that ensures a long-lasting bond without leaving residue.

Superior Barrier Properties: Offers outstanding thermal insulation, moisture resistance, and waterproofing.

Weatherproof Performance: Reliable for both indoor and outdoor applications without peeling or degradation.

Enhanced Durability: With a 150-micron total thickness, this tape is 2–3 times more durable than standard foil tapes.

Versatile Industrial Use: Ideal for sealing HVAC ductwork, electrical cabinets, heavy machinery, and circuit boards.

Safe & Easy Installation: Contains no toxic substances and is designed for fast, tool-free application.

Parameter:

| Product code | BKB-4 |

| Aluminum Foil Backing Thickness | 100 Micron |

| Total Thickness | 150 Micron |

| Adhesion to Steel | 18 N/25mm |

| Tensile Strength | 255 N/25mm |

| Service Temperature Range | -20 ~ +80 °C |

The outermost layer of fiberglass reinforced aluminum foil tape is a pure aluminum layer with a base thickness of 100 microns. This layer not only protects the surface but also acts as an effective moisture barrier, preventing water penetration and oxidation.

In particular, aluminum’s heat-reflective capability helps minimize heat absorption, keeping internal equipment stable.

The aluminum layer can also withstand temperatures up to 450°C, an impressive level that makes the product reliable for high-temperature environments such as factories, industrial zones, and HVAC systems.

The biggest difference of this tape lies in its core — a thin fiberglass layer. Fiberglass is a material with excellent toughness and heat resistance, commonly used in insulation and fireproof materials.

When integrated into the tape, it increases tensile strength up to 255 N/25mm while also reducing the risk of flame spread.

Fiberglass also prevents tearing during pulling, maintains shape stability over time, and resists deformation under mechanical impact or high temperatures.

The adhesive layer in 3W fiberglass aluminum foil tape is a premium acrylic adhesive, capable of strong bonding on both steel and aluminum surfaces with adhesion strength up to 18 N/25mm.

Notably, acrylic adhesive is solvent-free, ensuring user safety and environmental friendliness.

In addition, this adhesive performs well in humid conditions and temperature ranges from -20°C to +80°C, maintaining stable adhesion over long-term use. This is critical in applications such as duct sealing, HVAC joints, and specialized insulation systems.

Beyond its structure, fiberglass aluminum foil tape is widely preferred thanks to numerous superior advantages. From fire resistance to elasticity, mechanical durability, and moisture resistance, each feature is designed to optimize performance in harsh environments.

One of the product’s greatest strengths is its ability to withstand destructive temperatures up to 450°C, thanks to the aluminum and fiberglass layers. This temperature level exceeds the capability of most conventional tapes.

This feature is essential in industrial applications or fire-risk areas such as equipment rooms, electrical cabinets, and exhaust ducts.

Additionally, the fiberglass layer acts as a fire barrier, effectively preventing flame spread, especially in residential buildings and factories.

Besides thermal insulation, the aluminum and fiberglass layers also help reduce sound transmission, providing noticeable sound insulation for equipment and machine rooms.

In central air conditioning and air duct systems, using aluminum insulation tape also improves energy efficiency, reduces heat loss, and keeps internal spaces stable.

With a durable structure, fiberglass aluminum foil tape can withstand strong pulling force, impact, and vibration from industrial equipment without peeling or tearing.

Its superior moisture and waterproof resistance also protects metal structures, cables, and circuit boards from humidity and oxidation.

The aluminum layer combined with acrylic adhesive ensures long-term adhesion without edge lifting or cracking, even in outdoor use.

The tape contains no harmful substances, making it safe for users and environmentally friendly.

It also has good flexibility, is easy to cut and apply, and does not require special tools.

Thanks to its versatility and durability, fiberglass aluminum foil tape is an ideal choice for many industries — from construction and electrical systems to HVAC and equipment manufacturing — meeting insulation, protection, and fire-resistance requirements in harsh working environments.

In ventilation and HVAC systems, aluminum insulation tape is commonly used to:

Seal duct joints to prevent heat loss and air leakage.

Reinforce insulation layers, especially at intersections and corners.

Seal gaps in partitions to prevent flame spread.

In addition, in factory construction and civil works, it is used to:

Waterproof metal surfaces, roofing sheets, and aluminum walls.

Protect outdoor insulated pipes from UV rays and rainwater.

Improve insulation efficiency for hot and cold water pipelines.

With strong heat and moisture resistance, fiberglass aluminum foil tape is a long-term solution replacing conventional non-specialized tapes.

Electrical equipment, wiring systems, and circuit boards often require protection from moisture and high temperatures. Here, fire-resistant aluminum tape serves to:

Insulate hot wires and medium/high-voltage cables.

Protect electrical equipment from electromagnetic interference and corrosion.

Reinforce cable joints exposed to vibration or mechanical stress.

Thanks to high tensile strength and impact resistance, the product is also widely used in mechanical industries to:

Reduce machine vibration and extend equipment lifespan.

Protect painted metal surfaces during transportation and installation.

In factories, fiberglass aluminum foil tape is commonly used to:

Wrap heat-emitting equipment such as motors, generators, and industrial furnaces.

Prevent dust or chemical vapors from entering sensitive machinery parts.

Protect machine surfaces during maintenance or painting.

In household use, it is applied for:

Insulating ovens, refrigerators, and built-in gas stoves.

Reinforcing heat-leak areas to save energy consumption.

Its high versatility allows users to rely on a single roll for multiple purposes instead of purchasing different specialized tapes.

Despite its strong adhesion and durable structure, fiberglass aluminum foil tape must be used correctly to achieve maximum effectiveness and longer service life.

Before application, ensure the surface is dry, clean, and free from dust and oil. Poor cleaning reduces adhesive performance and may cause early peeling.

Basic steps:

Clean the surface with a dry cloth or mild alcohol solution.

Measure and cut the tape to the required length.

Apply evenly, pressing gently from the center outward to avoid air bubbles.

Press edges firmly to prevent peeling under moisture or vibration.

For high-temperature environments (above 60°C), the tape still performs well, but users should note:

Do not apply when the surface is excessively hot, as acrylic adhesive needs time to set.

Allow the surface to cool or use ventilation before application.

After applying, leave undisturbed for at least 30 minutes for optimal bonding strength.

Do not use on very rough surfaces such as raw concrete or uneven flooring.

Do not overstretch during application, as it may distort the fiberglass layer.

Do not apply directly onto open flames or temperatures beyond the aluminum layer’s tolerance.

Following proper procedures ensures maximum fire resistance, moisture protection, and insulation performance while extending service life.

Fiberglass reinforced aluminum foil tape is not just an auxiliary material but an optimal solution for many modern technical and industrial applications. With its intelligent three-layer structure, outstanding heat resistance, fire protection, and insulation capability, the product delivers high reliability. Choosing 3W Tape means enhancing quality and durability for every project.