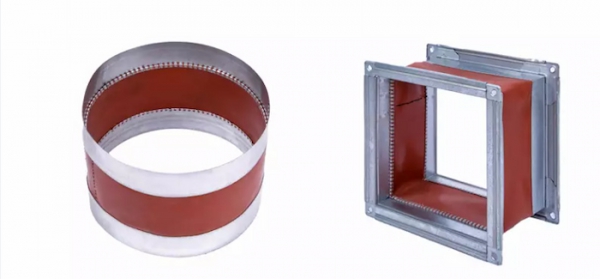

What is a Flexible Duct Connector?

A flexible duct connector is an elastic joint between a fan and an air duct in HVAC systems, helping reduce vibration, minimize noise, and balance pressure. Silicone-coated fiberglass fabric offers higher heat resistance, durability, and fire resistance than PVC-coated fabric, which is typically suitable only for standard residential systems.

A silicone-coated fiberglass flexible connector rated up to 280°C is an optimal choice for durability, safety, and performance in industrial ventilation systems.

Main Functions

-

Reduce vibration and noise transmitted from fans or motors to the duct system.

-

Absorb movement caused by thermal expansion or mechanical vibration.

-

Compensate for small installation misalignments between two metal duct ends.

Comparison of Two Common Types

| Criteria | Silicone-Coated Fiberglass Connector | PVC-Coated Fabric Connector |

| Main material | Fiberglass fabric with double-sided silicone coating | Polyester fabric with PVC coating |

| Working temperature | -40°C to +250°C | -10°C to +80°C |

| Fire & heat resistance | Excellent – non-flammable, slight shrinkage when exposed to flame | Poor – may melt or deform at high temperature |

| Mechanical strength & lifespan | High, resistant to vibration and aging | Medium, ages quickly under heat and UV |

| Air tightness & pressure | Good, suitable for high-pressure systems | Adequate for low-pressure residential systems |

| Chemical & oil resistance | Good, suitable for industrial environments | Moderate, less resistant to strong solvents |

| Typical applications | AHU, central fans, cleanrooms, industrial workshops | Residential ventilation, kitchen exhaust, small factories |

| Cost | Higher (silicone–fiberglass material) | Lower, easy to produce and replace |

Structure and Materials

Silicone-Coated Fiberglass Fabric

The key component enabling heat resistance up to 280°C is silicone-coated fiberglass fabric. The fabric density is 430 g/m², coated with silicone on both sides (130 g/m² total coating), enhancing heat resistance, waterproofing, and chemical resistance. Silicone protects the fiberglass core while blocking dust, toxic gases, and moisture, ensuring stable duct connections.

This silicone layer is also self-extinguishing, reducing fire spread risk and meeting Class A2 fire resistance, suitable for high-safety environments such as chemical plants, food factories, and electronics manufacturing.

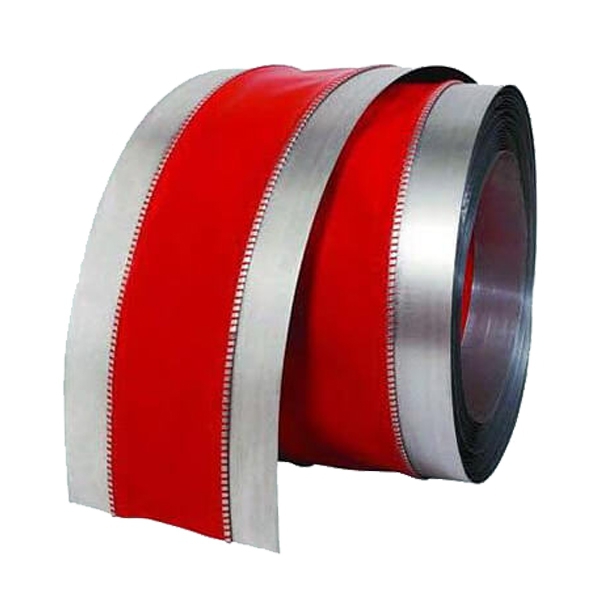

Galvanized Steel Strip Reinforcement

Both ends are reinforced with 0.35 mm thick galvanized steel strips, each 50 mm wide. These strips secure the connector to duct flanges while increasing structural strength and preventing tearing or deformation during operation.

The steel is double-side galvanized (60–65 g/m² coating) for improved corrosion and oxidation resistance, especially in humid, chemical, or outdoor environments.

Three-Layer Structure & Standard Size

A standard roll is 25 m long and built with three layers:

-

50 mm galvanized steel

-

150 mm silicone-coated fiberglass fabric

-

50 mm galvanized steel

Total width: 250 mm — ensuring flexible connection, easy installation, strong sealing, and optimal vibration and heat resistance.

Class A2 Fire Resistance Standard

The product meets Class A2 fire classification (EN13501-1) — non-combustible, producing minimal smoke and no flaming droplets.

This ensures that in case of sparks or high heat, the connector will not ignite, spread flame, or worsen fire hazards, making it suitable for:

-

High-rise buildings

-

Parking basements

-

Chemical plants

-

Data centers

Advantages of Using Flexible Duct Connectors

Flexible Installation & Maintenance

The connector can bend, flex, and expand, adapting easily to:

-

Angled joints

-

Limited installation space

-

Thermal expansion areas

For maintenance, technicians can remove only the connector section without dismantling the entire duct system — saving time and labor.

Reduced Operating & Replacement Costs

Compared with rigid joints or specialized metal ducts, flexible connectors are cheaper to produce and replace. Long lifespan, high heat resistance, and low maintenance help save significant system maintenance costs annually, especially in large projects.

Reduced Vibration, Noise & System Damage

Continuous fan operation can cause vibration leading to:

-

Joint damage

-

Loose flanges

-

Loud noise

-

Reduced fan lifespan

Flexible connectors absorb vibration and reduce noise transmission, improving durability and creating quieter environments — especially important in hospitals, hotels, offices, and low-noise factories.

Industrial Applications

HVAC Ventilation Systems

Flexible connectors reduce vibration from fans, maintain airtight sealing, and prevent noise transmission. With heat-resistant, fire-resistant three-layer construction, they ensure safe duct connections — particularly in concealed ceiling systems or high-heat environments.

Food Processing & Clean Environments

With Class A2 fire resistance, they are ideal for food, pharmaceutical, and electronics industries requiring clean, safe, low-contamination environments. Silicone surfaces resist bacteria and are easy to clean.

Operating range -40°C to 280°C prevents cracking or deformation under temperature fluctuations.

Large Duct Systems

Used in malls, factories, office towers, and industrial zones, flexible connectors absorb vibration, thermal expansion, and pressure variation, extending overall duct system lifespan and reducing maintenance.

Selection Guidelines for HVAC Systems

How to Identify Standard-Compliant Products

-

Clear technical specifications (fabric density, silicone coating, tensile strength)

-

Certified Class A2 fire resistance (EN13501-1)

-

Thick anti-corrosion galvanized steel reinforcement

-

Characteristic color (brick red), smooth fabric surface without wrinkles or peeling

Selection Criteria by Application

-

Temperature >200°C → must use silicone-coated fiberglass

-

High vibration → check tensile strength and fabric thickness

-

Continuous operation → choose higher mechanical durability

-

Chemical, food, or cleanroom environments → antibacterial, non-toxic, easy-clean materials

Common Mistakes

-

Using PVC or rubber connectors in high-temperature systems → melting or fire risk

-

Ignoring tensile strength → tearing after long operation

-

Incorrect width selection → air leakage and reduced ventilation efficiency

Always review manufacturer technical data and consult reliable suppliers before selection.

Conclusion

Whether in residential or industrial ventilation systems, flexible duct connectors play a crucial role in ensuring safety, performance, and durability. Choosing the right type improves system stability, reduces maintenance costs, and extends equipment lifespan. Always prioritize products with clear specifications, certified fire resistance, and reputable suppliers for long-term reliability.