What is a Flexible Duct Connector?

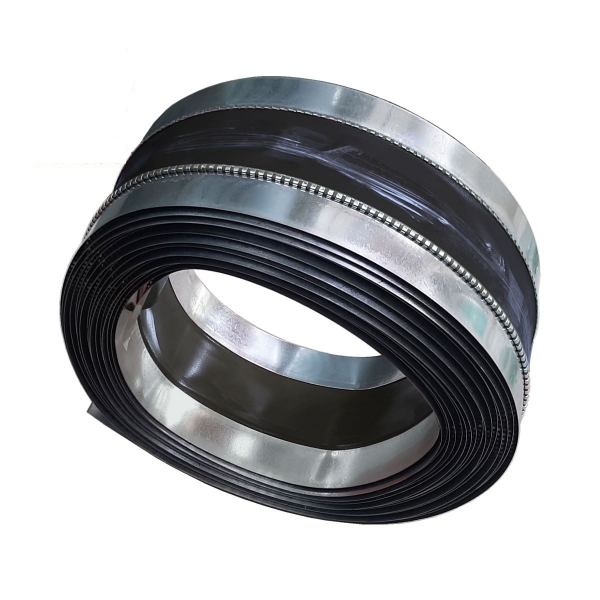

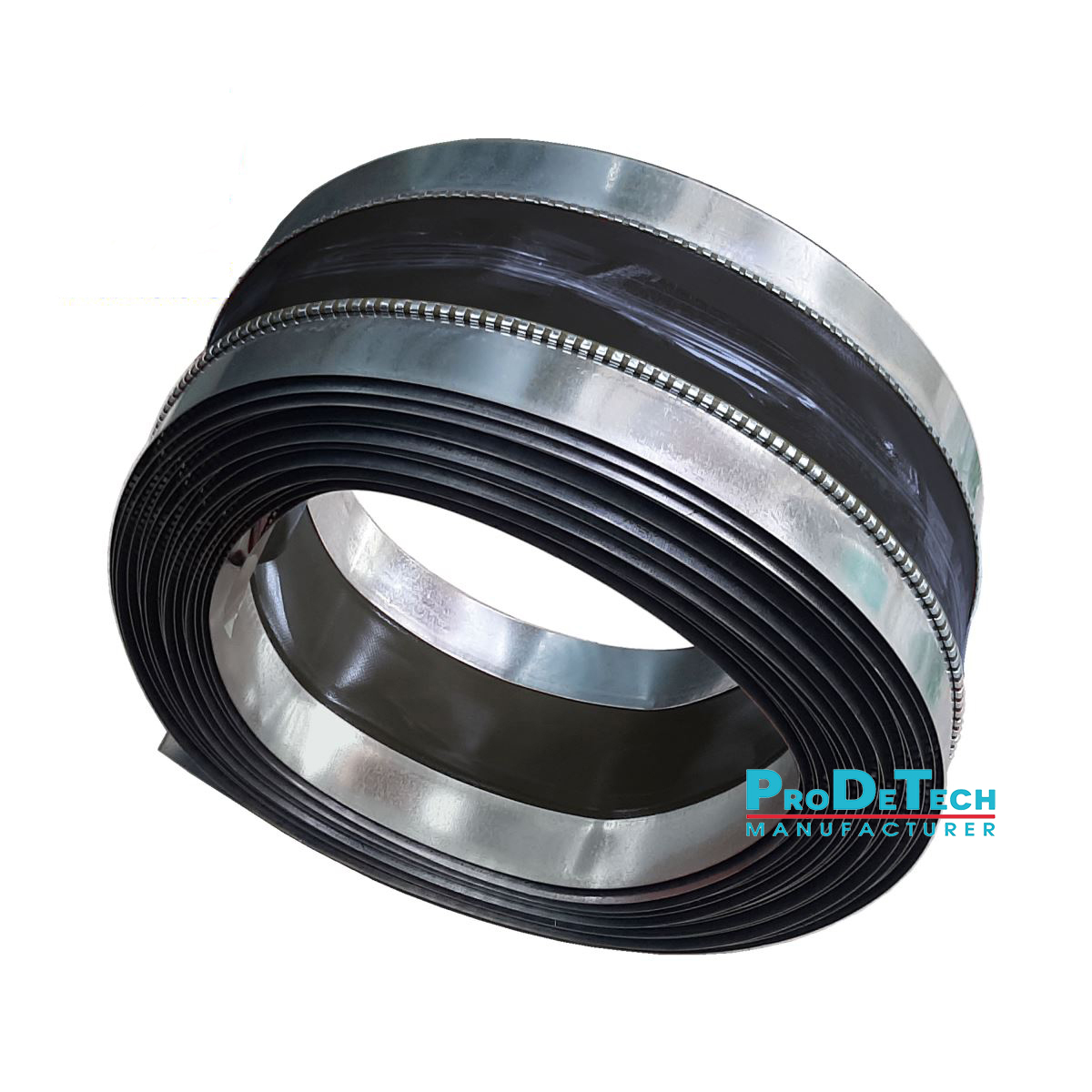

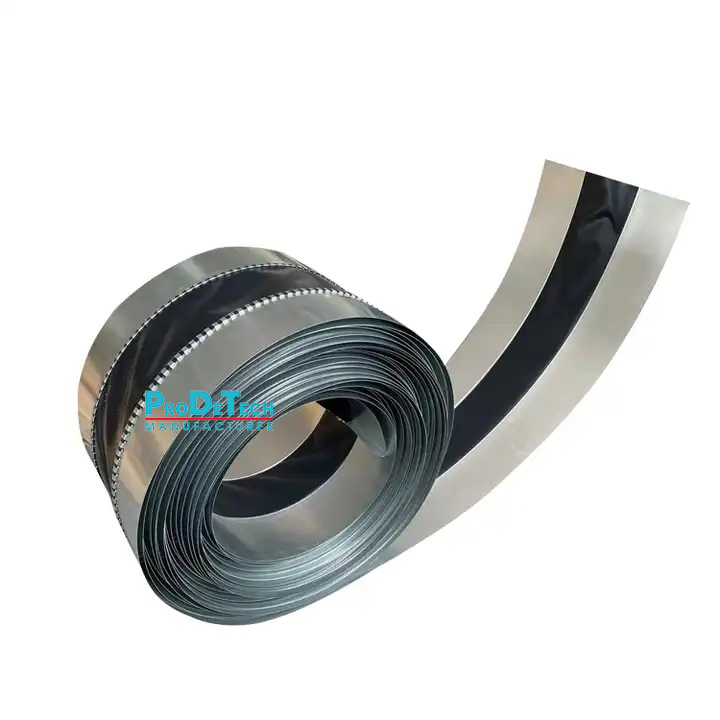

A flexible duct connector is a soft joint between a fan, FCU, AHU, or rigid duct sections, made from two galvanized steel (or stainless steel) strips combined with a fire-resistant fabric layer in the middle. Its main purpose is to reduce vibration, lower noise, and prevent mechanical shock from transferring to the duct system, helping the HVAC system operate more smoothly and last longer.

What is a Flexible Duct Connector and How is it Constructed?

A flexible duct connector is a soft joint made from industrial fabric with heat-resistant and fire-retardant properties, combined with galvanized steel or stainless-steel frames at both ends. It connects rigid duct sections in ventilation, air-conditioning, or smoke-extraction systems.

Key Functions

-

Reduce vibration and noise during operation

-

Compensate for thermal expansion caused by temperature changes

-

Limit vibration transmission from fan to ductwork

-

Easy to install, remove, and maintain

Its flexibility allows it to work in both fixed systems and systems with slight movement or mechanical impact.

Basic Structure of a Flexible Duct Connector

A typical flexible duct connector has a three-layer structure:

-

Middle layer: Heat-resistant PVC-coated fabric, density 180 g/m², improving fire resistance and air-pressure tolerance.

-

Two ends: 0.35 mm thick galvanized steel sheets, firmly pressed to ensure airtight connection with rigid ducts.

-

Standard configuration: 50 mm steel + 150 mm fabric + 50 mm steel → total width W250 mm, common industrial standard.

The fabric-to-metal joint is usually made by pressing or industrial stitching, ensuring no air leakage and long-term durability without peeling.

Key Advantages of Heat-Resistant Flexible Connectors

Heat Resistance up to 150°C

Operating temperature range: -30°C to 150°C.

Thanks to thick heat-resistant PVC and reinforced fabric structure, the connector maintains shape and elasticity in high-temperature environments such as:

-

HVAC equipment rooms

-

Industrial kitchen exhaust systems

-

Metallurgical and chemical plants

The fabric does not shrink, warp, or degrade at high temperatures, extending system lifespan.

Class B1 Fire Resistance for Safety

The product meets Class B1 fire-retardant standard, meaning:

-

Does not ignite easily when exposed to heat

-

Does not sustain flame for long

-

Reduces fire spread risk in enclosed duct systems

Required for: food processing plants, factories, shopping malls, and high-rise ventilation shafts.

Durability and Vibration Resistance

Designed to:

-

Reduce shock force from fan to duct (tensile strength up to 3000 × 2090 N)

-

Absorb vibration from nearby mechanical equipment

-

Resist tearing and fabric breakage (tear resistance 288.5 × 246.6 N)

This ensures stable operation, reduced maintenance, improved safety, and long-term cost savings.

Practical Applications

Industrial HVAC Systems

Flexible connectors are essential for:

-

Connecting fans to rigid ducts

-

Reducing vibration transfer

-

Reducing stress on fixed duct sections during thermal fluctuation

In 24/7 central HVAC systems, they help maintain stable airflow and pressure.

Food and Chemical Industries

Used due to:

-

Anti-bacterial and dust-resistant properties

-

Class B1 fire resistance meeting safety standards

-

Resistance to humidity, oil vapor, and mild chemicals

-

Easy cleaning and maintenance

Environments with Large Temperature Fluctuation

The connector withstands -30°C to 150°C without deformation or shrinkage, making it suitable for:

-

Tunnel and basement ventilation

-

Boiler and drying furnace areas

-

Heavy-machinery workshops

Ensures consistent ventilation, dust filtration, and cooling performance in both residential and heavy industrial environments.

Selection Criteria for High-Quality Flexible Connectors

Based on Technical Specifications & Usage

Consider:

-

Operating temperature range (prefer -30°C to 150°C)

-

Standard width W250 mm (50-150-50 mm) or custom size

-

Roll length typically 25 m/roll

-

Tensile strength ≥ 2500 N for continuous operation

Also determine:

-

Type of connected equipment (fan, round or rectangular duct)

-

Environmental conditions (dust, humidity, chemicals, UV)

Fire Safety and Mechanical Strength

Choose products with:

-

Class B1 fire resistance

-

Thick PVC-coated durable fabric resistant to moisture and chemicals

-

High tensile strength to prevent tearing in high-pressure systems

Proper selection ensures safer operation and reduces risk of system failure.

Notes on Size, Color, and Brand

-

Common colors: black or dark gray (less dirt and fading)

-

Choose clear brand, model code, and warranty

-

Custom sizing available from some manufacturers

-

Verify samples or certifications to confirm material quality

Conclusion

PVC-coated flexible duct connectors are not just auxiliary materials but key components ensuring durability, safety, and efficiency of HVAC systems. With heat resistance up to 150°C, Class B1 fire safety, and flexible structure, they fully meet demanding industrial requirements. Choosing the right connector improves system performance and extends equipment lifespan.