Description:

Superior Thermal Insulation: Maintains stable cooling performance by preventing thermal bridging.

Moisture & Mold Resistance: Effectively blocks moisture ingress to protect the integrity of the insulation layer.

High-Tack Adhesive: Ensures a permanent bond that will not peel, even in harsh environmental conditions.

High Temperature Stability: Capable of withstanding temperatures up to 240°C, making it suitable for hot-process equipment.

Optimized for HVAC Materials: Engineered for excellent adhesion to closed-cell rubber foam and copper piping.

Versatile Applications: Ideal for HVAC systems, air conditioning units, and industrial pipe insulation.

Eco-Friendly & Safe: Non-toxic formulation, safe for both users and the environment.

Contractor Grade: Trusted and recommended by professional M&E (Mechanical & Electrical) contractors.

Parameter:

| Product code | BKB-3 |

| Adhesion to Nitrile Rubber (NBR) Foam | 0.73 N/mm - ASTM D429 |

| Tensile Strength | 12.46 MPa - ASTM D412 |

| Operating Temperature Range | < 240 °C - ASTM E1131 |

| Dimensions | W50mm x 50mL (50m/roll) |

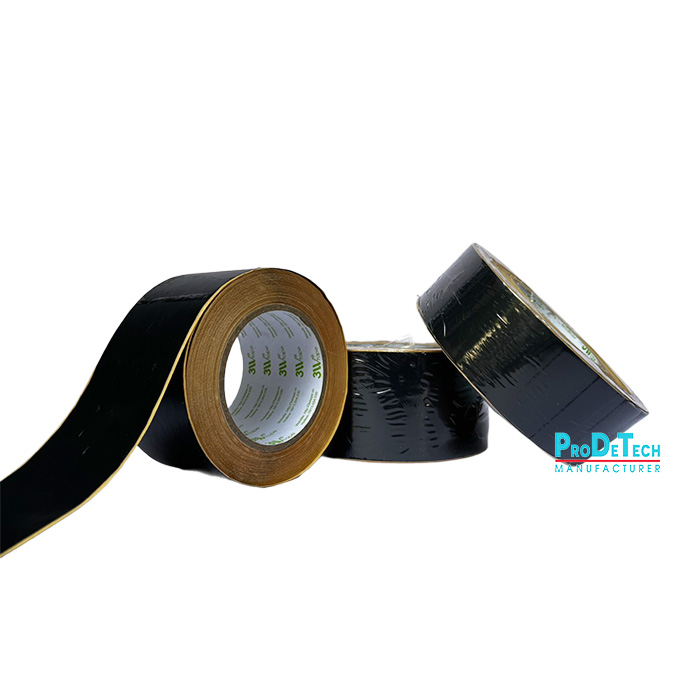

The outermost layer is a premium black PVC film that provides excellent waterproofing, moisture resistance, and mechanical abrasion protection throughout its service life. Thanks to its chemical resistance, this PVC layer prevents degradation when exposed to oils and industrial chemicals—an important advantage in HVAC systems and mechanical equipment.

The adhesive layer uses pressure-sensitive acrylic technology, delivering strong bonding on various surfaces, especially rubber foam insulation. According to ASTM D429, adhesion strength reaches 0.73 N/mm, ensuring long-term durability without peeling. This layer firmly secures insulation materials, preventing energy loss within the system.

The innermost layer is a specially coated silicone release paper that protects the adhesive from drying out or contamination during storage and transportation. It peels off cleanly without residue, enabling fast and tidy installation while saving time for engineers and maintenance teams.

The high-quality PVC material combined with acrylic adhesive enhances thermal insulation performance and minimizes heat transfer through the material surface. When applied tightly to rubber foam insulation, the tape acts as a sealing layer that improves cooling or heating efficiency and reduces energy consumption.

With strong moisture resistance, the tape effectively prevents mold growth—especially important in high-humidity environments such as basements, factories, and cold storage. Its mechanical strength allows it to withstand impacts and vibration, making it suitable for outdoor installations and continuously operating industrial equipment.

According to ASTM D412, tensile strength reaches 12.46 MPa, outperforming common insulation tapes. The product is free from harmful substances, non-irritating to skin, safe for installers, and environmentally friendly—helping projects achieve green building certifications.

One of the most common uses is sealing insulation on copper pipes, chilled water pipes, and flexible air ducts in central air-conditioning systems. Black PVC tape covers rubber foam insulation completely, preventing heat loss and condensation, ensuring stable cooling performance and longer insulation lifespan.

Example: In VRV or concealed duct systems, proper application can reduce heat loss by up to 15% compared with improper sealing.

With strong electrical insulation properties, the tape is also used to wrap compressors, refrigerant pipes, and capacitors—protecting them from environmental temperature and humidity. In cold storage or technical rooms, this protective layer prevents corrosion and performance degradation over time.

Beyond insulation, the tape can absorb vibration and noise due to the elasticity of the adhesive and PVC film. Applied under ducts or at equipment-to-support contact points, it helps reduce sound and vibration transmission, ensuring quieter system operation.

| Feature | Black PVC Tape | Ordinary Tape |

| Thermal insulation | Excellent | Poor, transfers heat easily |

| Moisture resistance | Waterproof, mold-resistant | Prone to mold and peeling |

| Adhesion durability | Long-lasting, no peeling | Short lifespan |

| Long-term durability | Withstands heat, humidity, vibration | Easily tears or detaches |

High-quality PVC tape is designed for harsh environments, ensuring long-term adhesion without frequent replacement, unlike ordinary tape which deteriorates quickly.

Although black PVC tape may cost more than regular tape, its durability, insulation performance, energy savings, and reduced replacement costs make it a more economical long-term investment—especially in professional installations.

Designed specifically for rubber foam insulation bonding, it fully meets HVAC, central air-conditioning, ducting, and hot/cold piping insulation requirements. High heat resistance, moisture protection, and long-term adhesion reduce installation and maintenance risks.

Used in projects such as solar power plants, office buildings, hotels, and industrial cooling systems.

Free from harmful substances such as lead, mercury, and VOCs—commonly restricted in green construction. Acrylic adhesive is tested to be non-irritating and safe for users and electronic equipment, making it suitable for LEED, LOTUS, and WELL certified projects.

Prodetech black PVC insulation tape is widely trusted by M&E contractors, with thousands of meters used monthly. It is readily available through distributors and supported by technical assistance when needed.

Conclusion

Prodetech black PVC tape is an optimal solution for professional thermal insulation systems. Durable, easy to apply, and compliant with international technical standards, it offers reliable, long-term performance for safe and efficient insulation.