What is Apollo Acrylic A100 Sealant?

Composition and Manufacturing Technology

Apollo Acrylic Sealant A100 is a single-component, water-based acrylic sealant, classified as a premium acrylic product made from imported, environmentally friendly raw materials. It is not a conventional silicone sealant, but a product combining advanced acrylic technology with strict quality control under international ASTM standards.

One of its key advantages is the ability to self-fill small cracks and allow easy application without specialized tools. Notably, the sealant can be painted over after fully curing, improving aesthetics without affecting wall or interior paint layers.

Difference Between Silicone and Acrylic Sealants

Many people confuse silicone and acrylic sealants. In reality, Apollo A100 belongs to the water-based acrylic sealant group, mainly used for interior joints that do not require high elasticity.

| Criteria | Apollo Acrylic A100 | Typical Silicone Sealant |

| Base | Water-based | Solvent-based |

| Paintable | Yes, after curing | Not paintable |

| Application | Dry interior | Interior & exterior |

| Elasticity | Low | Medium to high |

| Skin-dry time | ~12 minutes | Usually 30+ minutes |

Thus, Apollo A100 is ideal for wall cracks, door frames, gypsum ceilings, where high flexibility is not required but paintability and safety are important.

Outstanding Advantages of Apollo A100 Silicone Sealant

Adhesion and Mold Resistance

One of the greatest advantages of Apollo A100 is its excellent adhesion to a wide range of materials such as: concrete, cement board, brick, gypsum, wood, aluminum, PVC, and more. In particular, the product also features effective anti-mold properties, helping prevent discoloration, peeling, or deterioration during long-term use.

The sealant contains no harmful solvents, ensuring safe use in enclosed spaces such as bedrooms, offices, apartments, and childcare facilities.

Faster Application Compared to Cement

Time is an important factor in modern construction. While cement typically requires 2–3 hours to dry on the surface, Apollo A100 takes only about 12 minutes to set. This helps accelerate work progress and significantly reduce labor costs.

This advantage is especially suitable for projects requiring fast, clean, and neat construction such as offices, residential houses, and high-end apartments.

Paintability and Proper Painting Conditions

Unlike many acid-based or neutral silicone sealants that cannot be painted, Apollo A100 can be fully painted after curing. However, for optimal results, you should note:

-

Full curing time: at least 24 hours under normal conditions (30°C, dry environment)

-

Use compatible paint: water-based acrylic paint, avoid strong solvent-based paints

-

Test on a small area before large-scale application

Being paintable allows the sealed joint to become completely “invisible,” matching the color of the surrounding wall, door, or materials.

Apollo A100 Compatible Materials & Applications

Recommended Materials for Application

According to technical documentation from Apollo Silicone, the Acrylic Sealant A100 series provides excellent adhesion to the following common building materials:

-

Concrete & Aerated Concrete: Ideal for walls and structural surfaces.

-

Panels & Tiles: Suitable for gypsum ceilings, fiber cement boards, and ceramic tiles.

-

Finishing Materials: Bonds effectively to wood, PVC panels, and aluminum profiles.

-

Interior Joints: Perfect for window frames, wall gaps, and interior ceiling/partition joints.

-

Aesthetic Sealing: Specifically designed for filling small gaps, joints requiring high aesthetics, and low-movement connections such as door frames or hairline cracks in gypsum ceilings.

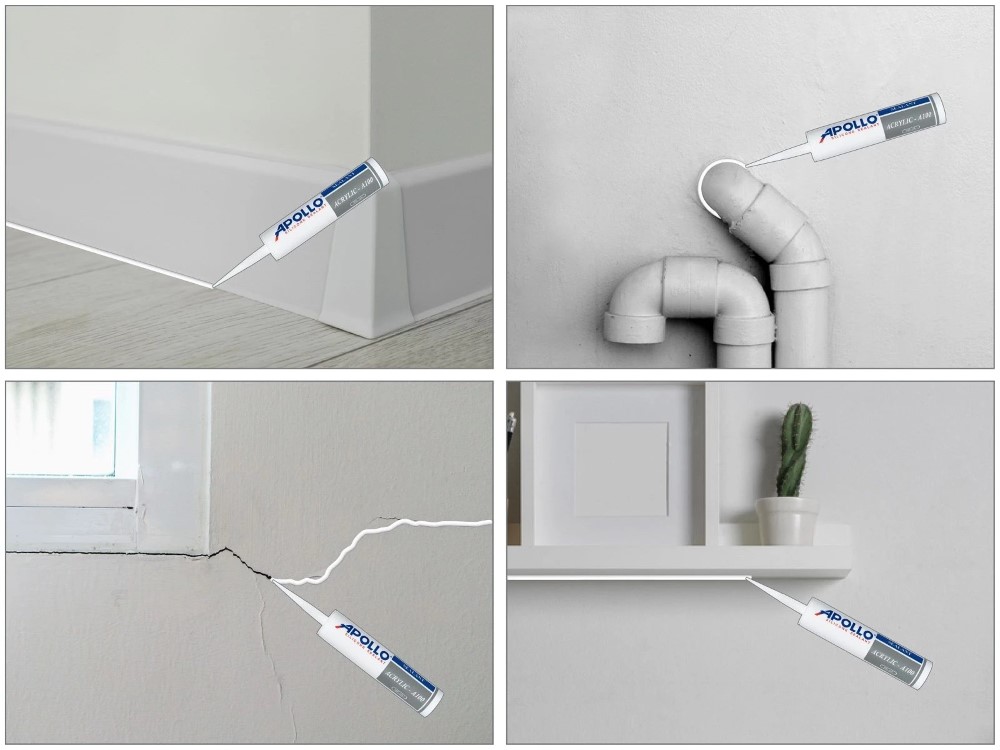

Best-Suited Interior Applications

The versatility of Apollo A100 makes it the preferred choice for several specific interior locations:

-

Skirting Boards: Sealing the gap between walls and baseboards.

-

Frame Perimeter Sealing: Filling edges around windows and doors.

-

Ceiling Transitions: Connecting joints between walls and gypsum ceilings.

-

Interior Finishing: Patching small cracks during the final interior decoration process.

-

Technical Penetrations: Sealing gaps between PVC utility pipes and wall structures.

-

Environmentally Sensitive Areas: Due to being odorless, solvent-free, fast-drying, and paintable, it is ideal for homes, offices, hotels, and showrooms.

Important Usage Constraints

Applications to Avoid

Despite its versatility, Apollo A100 is not suitable for the following conditions:

-

Wet or Outdoor Areas: Do not use outdoors or in areas with frequent water exposure (e.g., bathrooms, eaves, or aquariums).

-

High-Movement Joints: Not intended for joints requiring high elasticity, such as metal panels, rolling doors, or thermal expansion joints.

-

Structural & High-Vibration Sites: Not for use in load-bearing structures or areas subject to constant heavy vibration.

-

Extreme Temperatures: Avoid areas with significant temperature fluctuations or direct exposure to intense sunlight.

-

Performance Risk: Improper application may lead to adhesive failure, loss of bonding, or recurring mold growth.

Proper Application Guide for Apollo A100 Sealant

Surface Preparation and Application

Before application, ensure the surface is clean, dry, free of oil, and free of cement dust. For metal surfaces, lightly sand with sandpaper to improve adhesion. If sealing close to walls or corners where sealant may smear, apply masking tape along both edges for protection.

Preparation steps:

-

Completely clean the surface to be sealed

-

Apply masking tape for shaping if necessary

-

Prepare the sealant gun and smoothing tools

Nozzle Cutting, Sealant Application, and Smoothing Guide

Correct sealant application process:

-

Cut the nozzle tip at a 45-degree angle, sized appropriately for the joint width

-

Attach the nozzle to the caulking gun and apply with steady, continuous pressure

-

Push the sealant along the joint in one continuous motion, ensuring full contact with both sides

-

Use a finger dipped in soapy water or a specialized silicone tool to smooth the sealant surface

-

Remove masking tape immediately after smoothing for clean, sharp edges

Note: Do not leave the sealant exposed to air for too long before use to prevent the nozzle tip from drying out.

Important Notes During Application

-

Do not apply in rainy conditions or high humidity, as it may affect adhesion

-

Do not reuse hardened sealant remaining in the nozzle

-

Ideal application temperature: 25–30°C

-

Avoid applying in areas with large temperature fluctuations such as near furnaces, air conditioners, or sun-exposed glass surfaces

Careful application not only ensures a clean and smooth seal line but also guarantees long-lasting adhesion.

Apollo A100 silicone sealant is an ideal solution for modern interior construction projects where high aesthetics and safety are required. Thanks to its strong adhesion, odorless formula, paintability, and ease of use, this product has become a trusted choice for millions of users for over 20 years. If you need an effective, economical, and environmentally friendly sealant, Apollo A100 is definitely worth considering.