Composition of Rockwool Mineral Wool

What stone is mineral wool made from?

The main raw materials used to produce Rockwool mineral wool are two natural stones: Basalt and Dolomite. These stones have high mechanical strength, excellent heat resistance, and are widely available in nature.

Both stones are crushed, mixed in precise technical ratios, and then melted at extremely high temperatures—up to 1,600°C—to form a uniform molten mineral mixture.

Rockwool Fiber Formation Process

Immediately after melting, the molten mixture is spun at high speed in a centrifugal system to create fine mineral fibers. This stage determines fiber bonding and the final performance of the product.

The fibers are then compressed or shaped into rolls, boards, or pipe sections, depending on the intended application. Finally, the product is surface-treated, trimmed, and packaged according to safety standards.

This modern manufacturing process allows Rockwool to maintain an ultra-fine fiber structure, enhancing thermal insulation, sound absorption, and fire resistance without using harmful chemicals.

Key Features of Rockwool Mineral Wool

Effective Thermal Insulation

Rockwool has a low thermal conductivity of approximately k = 0.0361 W/m·K, helping prevent heat loss and maintain stable indoor temperatures, reducing energy costs in both hot and cold seasons.

Example: When installed under metal roofing, room temperature can drop by 5–10°C compared to non-insulated spaces.

Fire Resistance up to 750°C

Rockwool can withstand temperatures up to 750°C and is non-combustible, making it ideal for:

In case of fire, Rockwool helps slow flame spread, reducing damage and increasing evacuation time.

Excellent Sound Insulation

Its dense interwoven fiber structure absorbs and reduces noise effectively. Higher density improves sound absorption and reduces echo and resonance.

Common applications include:

Water-Resistant and Safe for Health

Rockwool does not absorb water, does not support mold growth, and remains stable in humid environments. It contains no CFC or HCFC, emits no toxic gases, and is environmentally friendly—meeting green building standards.

Common Types of Rockwool

1. Roll (Blanket) – Flexible for large surfaces

Used for roofs, ceilings, drywall, and partitions.

2. Board (Rigid Panel) – High strength for walls and ceilings

Used for exterior walls, acoustic partitions, studios, and technical rooms.

3. Pipe Section – For piping systems

Used for hot/cold water pipes, HVAC ducts, and boiler pipelines.

-

Pre-formed cylindrical shape

-

Inner diameter DN15–DN300

-

Often foil-faced or wire-mesh reinforced

Practical Applications of Rockwool

Residential and Commercial Buildings

Used in houses, apartments, offices, hotels, and schools to:

-

Reduce noise from roofs and partitions

-

Stabilize indoor temperature

-

Improve fire safety and building durability

Pipe and HVAC Insulation

Used in food, chemical, and cement plants, boilers, and HVAC systems to:

-

Retain heat and reduce energy loss

-

Prevent condensation and corrosion

-

Improve operational safety

Acoustic Applications

Ideal for generator rooms, studios, cinemas, and conference halls to reduce echo and noise transmission.

Food Processing Industry

Maintains stable temperatures in production lines, provides fire protection, and ensures hygienic conditions.

Selection and Installation Guide

Choose the right type based on application

| Application |

Recommended Type |

Suggested Density |

| Metal roof / ceiling |

Foil-faced roll |

40–60 kg/m³ |

| Acoustic walls |

Rigid board |

60–100 kg/m³ |

| Hot/cold pipelines |

Pipe section |

80–120 kg/m³ |

| Studio / karaoke |

Acoustic board |

80–100 kg/m³ |

| Boilers / factories |

Heavy-duty board/pipe |

100–120 kg/m³ |

Installation Tips

-

Cut material accurately and evenly

-

Wear gloves and protective glasses

-

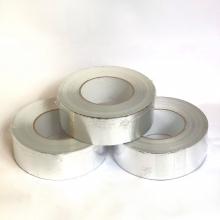

Use aluminum tape or stainless fasteners for fixing

-

Avoid water exposure during outdoor installation

-

Seal pipe joints with fire-resistant aluminum tape and protective outer cladding

With high heat resistance (up to 750°C), excellent thermal and acoustic insulation, and long service life, Rockwool mineral wool is a reliable solution for both residential and industrial applications. Choosing the right type and installing correctly ensures energy efficiency, safety, and long-term performance.